Description

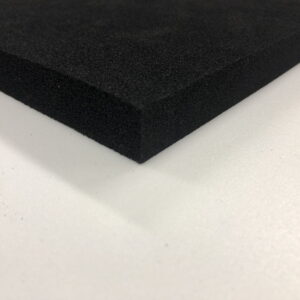

EPDM 120kg Resilient Building Tape – Waterproof & acoustic grade – 10mtr rolls, various widths & thicknesses

Made from 120kg density EPDM, resilient tape offers great anti vibration and helps improve acoustic performance. This tape is supplied with a double sided tissue tape to allow easy adhesion to a multiple of surfaces. The main application being construction to help minimise sound transfer between joints.

In addition to this EPDM provides a waterproof seal, thermal durability, and electrical resistivity making it an ideal candidate for electrical engineering and automotive applications.

Features & Benefits

- 120 kg density EPDM foam – durable, resilient material for vibration & acoustic dampening

- Waterproof & moisture resistant – resists ingress, ideal for damp environments

- Double-sided adhesive backing – easy application, sticks well to concrete, metal, plaster, wood

- Thermally stable – suitable for wide temperature ranges (-30°C to +80°C typical, verify for your variant)

- Fire class / safety – if you have a fire rating, mention it (e.g. Class O, BS 476 etc)

- Versatile sizes – multiple widths & thicknesses available, lengths of 10m

Typical Applications

- Vibration damping in structural joints

- Sound insulation between panels / partitions

- Sealing joints to reduce airborne sound transfer

- Pipe and conduit penetrations (interior use)

- Waterproof sealing in damp or wet areas

- Interior lining where moisture or thermal changes occur

Key Specifications

- Material: EPDM foam, 120 kg density

- Width / Thickness options: 25 / 50 / 75 / 100 mm widths × 3 or 6 mm thickness

- Roll length: 10 metres

- Adhesive backing: double-sided tissue tape

- Temperature range: approx -30°C to +80°C (verify from datasheet)

- Fire performance: (add rating if known) e.g. Class O or BS 476 (if applicable)

- UL94 rating

Suitable Surfaces

- metals – aluminium, steel, galvanised steel, zinc & copper

- painted or powder-surfaces

- plastics – rigid PVC, ABS, acrylic, polycarbonate (avoid oily plastics like PE/PP unless primed)

- wood – sealed, painted, varnished timber (not raw or dusty)

- glass – clean with IPA before use

- concrete/masonry – when smooth, sealed or primed with PVA/acrylic primer

- plasterboard & MDF – once sealed or painted

How to Apply

- Prepare the surface: clean, dry, and free from dust or grease. Use isopropyl alcohol (IPA) for degreasing. Prime porous surfaces if needed.

- Measure & cut: cut to length with a sharp knife or scissors.

- Peel & apply: peel back the release liner gradually while pressing the tape firmly into place.

- Press down: use firm pressure or a roller to ensure full contact and remove air bubbles.

- Finish: check edges are secure; full bond strength develops within 24 hours.